Wherever workpieces cannot be held with conventional clamping devices, vacuum is an ideal alternative. This clamping method is the first choice, especially for thin-walled or non-magnetic materials. Large parts, on the other hand, are clamped plane-parallel and vibration-free using the downforce created by vacuum.

Vacuum clamping opens up the possibility of more efficient production. With certain workpiece shapes, only two set-ups are required for all-side machining. This not only saves a lot of time and achieves greater productivity, but also enables more accurate component machining. In addition, the service life of tools is considerably increased by the vibration-free machining, which results in noticeable time and cost savings

With over 40 years of experience, Witte is one of the world's most experienced and innovative specialists in vacuum clamping technology. Their portfolio includes both conventional clamping methods and special clamping techniques. For example, freeze clamping (Ice Vice) for very small or geometrically undefined workpieces or mould clamping technology (Weiguss) for prototypes and small series.

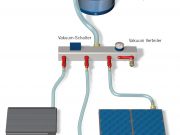

Vacuum chucks allow foils and extremely fine structures to be clamped absolutely flat - also excellent for fixing wafers and electronic foils. The programme is rounded off by grid vacuum chucks for heavy machining work such as grinding, milling and turning, as well as units for geeration of vacuum, liquid separators, accessories and consumables.

Status: May 2019