With VAC-MAT from Witte, workpieces can be completely machined in one clamping process. Up to 70 percent of the clamped material can be milled away without the vacuum breaking down or milled parts unintentionally being released. At the same time, there is no need for costly reworking, such as breaking out workpieces, deburring or clamping with clamps or double-sided adhesive tape.

Vacuum chucks are extremely versatile. However when it comes to milling openings and contours or processing fine, thin materials, for example, they reach their limits. Machining cutouts in particular requires special attention: With conventional clamping methods, it is difficult to mill through workpieces. Separated parts of the workpiece could come loose and cause accidents. Therefore, the areas to be removed are usually only milled. This results in laborious reworking: The remaining material then has to be separated and deburred by hand.

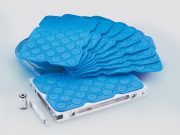

Using Witte’s clamping system VAC-MAT accelerates and facilitates such processes considerably. VAC-MAT is a vacuum chuck that is covered with elastic polymer mats. The thin, soft mats are provided with vacuum suction holes through which the air between the workpiece and the support surface is diverted. On the underside of the mats there are lugs for positioning on the vacuum chuck. VAC-MAT enables milling of through cuts, slots and the like. The process of machining contours and chamfers - otherwise only possible with special chucks – can successfully be carried out in the same process.

Similar to grid plates, the mats are also suitable for different processes and materials. Working with the VAC-MAT system is also made easier by the fact that only 60 percent of the vacuum chuck has to be covered with a component. It is not necessary to cover or limit the unused clamping surface.

For large-format chucks, the VAC-MAT chuck modules are coupled together with simple adapters thus enabling end-to-end vacuum supply.

Precise machining with VAC-MAT is supported by the accuracy of the mats with a thickness tolerance of 0.04 mm. Recesses on the outer areas of the mats allow stops to be used so that the workpiece can be aligned more easily.

The polymer mats are also suitable for wet work with common coolants and can be used without restrictions up to a temperature of 40°C. VAC-MAT is reusable - only the mats damaged by the machining process need to be replaced.

Status: May 2019