ALUFIX from Witte is the globally proven clamping and fixturing system for reproducible workpiece fixtures in dimensional measurement technology and production technology. The applications of the modular system range from the aerospace and automotive industries to medical and biotechnology.

Thanks to their precision and flexible variety, ALUFIX sets are used very widely. Among other things, they are used for measuring and checking fixtures, assembly and welding devices as well as master jigs, support structures for cubings and gauges. They are also used in prototype construction, model construction and for design developments, for example as a basis for clay models.

Material and precision

The elements of the modular ALUFIX product range are made of high-strength aluminum. This guarantees the best material quality, durability and resilience. Further design advantages are the high stability with extremely low weight. As well as the extraordinary precision thanks to the all-round finely machined individual parts. The standard, also all-round anodized coating offers high wear protection - optionally in material colour or black.

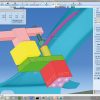

Thanks to the “permanently installed” high basic accuracy of the 100 percent flat sides on elements, practically every ALUFIX cuboid and every single one of its holes can be used as a reference in fixtures. When using a measuring arm, for example, any attachment points can be selected and incremental measuring can be carried out without any loss of accuracy.

Reproducibility and retooling

Of course, all devices implemented with ALUFIX can be reliably reproduced

In this point, too, ALUFIX is characterized by its "repeatability": The consistent implementation of the modular building block system allows unrestricted, long-term multiple use of practically all standard elements built into fixtures.

ALUFIX fixtures can be built from standard catalog elements without complex modifications, such as mechanical processing. Additions and modifications are possible at any time, as is dismantling in order to generate a completely new solution from the individual parts.

Thanks to this multiple retooling concept alone, it is possible to achieve a considerable cost advantage with ALUFIX compared to common throw away devices from the second application onwards - and thus a quick return on investment.

System sizes and versions

ALUFIX is available in four system sizes: For optical measurement and recording of small parts; for medium to small component fixtures; for medium-sized to large fixtures for assembly parts, meisterbocks etc; as well as for holding large and heavy parts.

In addition to the ALUFIX CLASSIC version made of high-strength aluminum, Witte offers ALUFIX ECO, a particularly economical variant of the system made of medium-strength aluminum for normal use and moderate re-use intervals.

As ALUFIX COLOR, all basic sets of the clamping and fixing system are also available in black anodized. They are specially designed for the use of optical scanning systems, for which the black components remain almost "invisible". This means that there is hardly any need to rework the scanned point cloud in order to virtually separate the component from the fixture.

The ALUFIX modular concept is perfected by the freedom to be able to combine all system sizes and designs with one another with virtually no restrictions.

A wide range of corresponding solutions complements the modular system. For example, with base / structure plates - optionally static, movable, driven or automated. Or with special fixtures and systems, such as loading stations, modelling tables and units.

Stand: May 2019