Systems

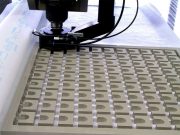

Vacuum clamping with Vilmill from Witte is always the solution of choice when you want to machine numerous small components from a large-format workpiece.

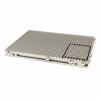

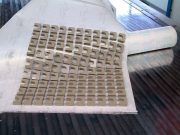

The vacuum clamping system Vilmill consists of a fleece-like, coated film, a vacuum chuck and a powerful pump system for vacuum supply. The Villmill film is placed between the chuck and the workpiece. Due to the heat generated during machining, the special surface coating "bonds" the workpiece to the Vilmill film. This holding effect of Vilmill provides additional process reliability. Further, the removal of the machined parts from the machine is much easier.

Requirements for use

- minimum suction power 0,25m² per 250 - 300 m³ / h

- high vacuum

- spindle speed > 20,000 rpm

- grid plate with grid 10mm

- specific milling strategy; retracting and extending the milling tool via programmed ramps